MASS PRODUCTION

CASE STUDY

How Tronix3D was able to streamline BluLine’s Assembly Process.

HOW WE STREAMLINED THE ASSEMBLY PROCESS

OVERVIEW

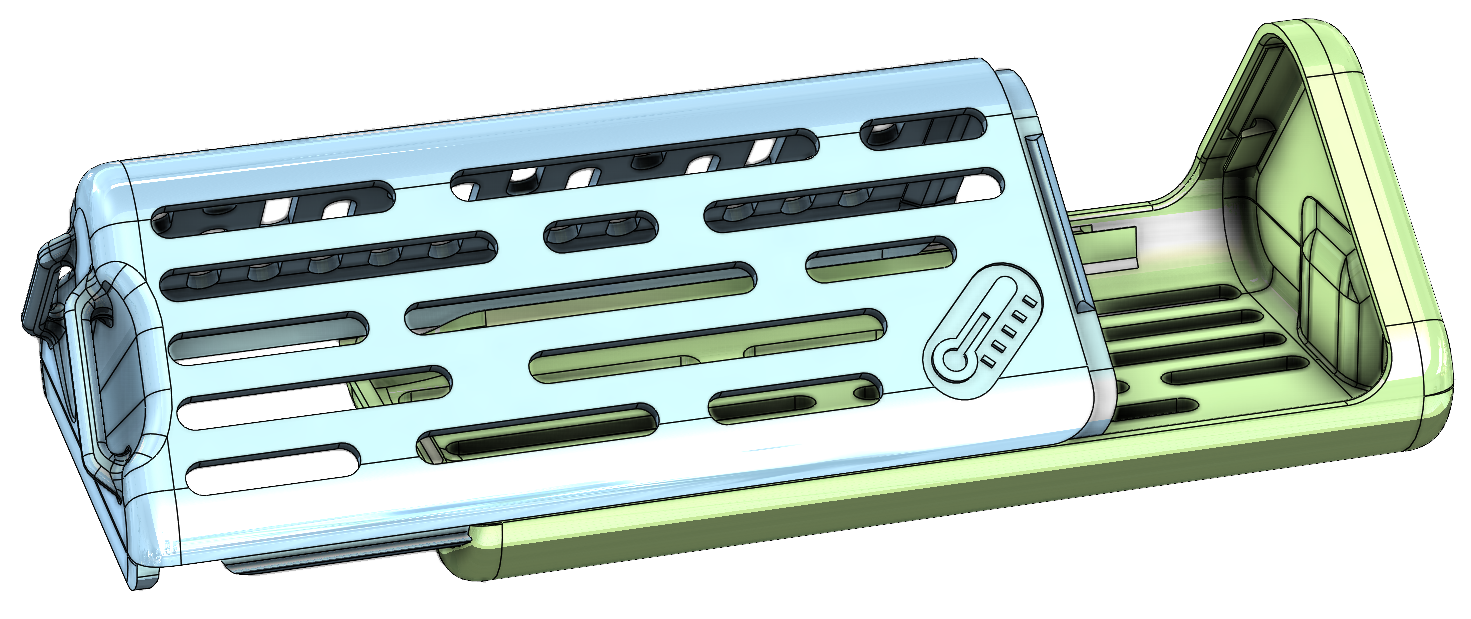

BluLine Solutions, renowned for its temperature monitoring technologies, sought to enhance the assembly process of their temperature sensor housing. After manufacturing the housing, which involved a two-piece assembly designed for gliding and secure locking, the next crucial phase was efficient assembly. This case study outlines how we streamlined BluLine Solutions' assembly process for their temperature sensor housing.

THE CHALLENGE

Understanding the Assembly Process

The initial phase involved acquiring a thorough understanding of the assembly process. Through close collaboration with BluLine Solutions, we discerned the challenges encountered during assembly and pinpointed areas with potential for enhancement. Our objective was to refine the process for reduced assembly time and sustained product quality.

TRONIX3D EXPERTISE

Designing for Assembly Efficiency

With the goal of augmenting assembly efficiency, we embarked on design modifications. We ensured that the housing components were adeptly designed for seamless gliding and secure locking, enabling rapid and effortless assembly.

Small Change in Design from Assembly Lessons Learned

As the production progressed, it was evident that a small change in design could significantly improve the assembly process. Drawing insights from the assembly lessons learned, a minor modification was made to the design, which had a substantial impact on ease of assembly and efficiency.

Assembly Aids

Recognizing the critical nature of adeptly handling sensor packs during assembly, we utilized our FDM Printers to create assembly aids. We manufactured a series of tailor-made trays purposed to securely hold the sensor packs during assembly. These trays facilitated easy access and swift insertion of the sensor packs into the housing, significantly expediting the assembly process.

CONCLUSION

By focusing on enhancing assembly efficiency, implementing insightful design modifications, and introducing custom assembly aids, we successfully streamlined the assembly process for BluLine Solutions' temperature sensor housing. The outcome was a notable reduction in assembly time and heightened product quality. Our cooperative approach with BluLine Solutions and the incorporation of innovative solutions exemplify our dedication to assisting clients in achieving exceptional operational outcomes.

Does your business face similar manufacturing challenges? Connect with Tronix3D today and discover how our expertise can help you optimize your processes, reduce costs, and produce high-quality products.