Busting The Top 5 Myths About Additive Manufacturing with Tronix3D

With the rapid growth and evolution of 3D printing technology, there's no shortage of excitement and innovation. However, along with this progress comes a slew of misconceptions that often cloud public perception. To set the record straight, we're going to debunk the top 5 myths about additive manufacturing in a fun, informative, and enlightening manner. So, buckle up, and let's separate fact from fiction!

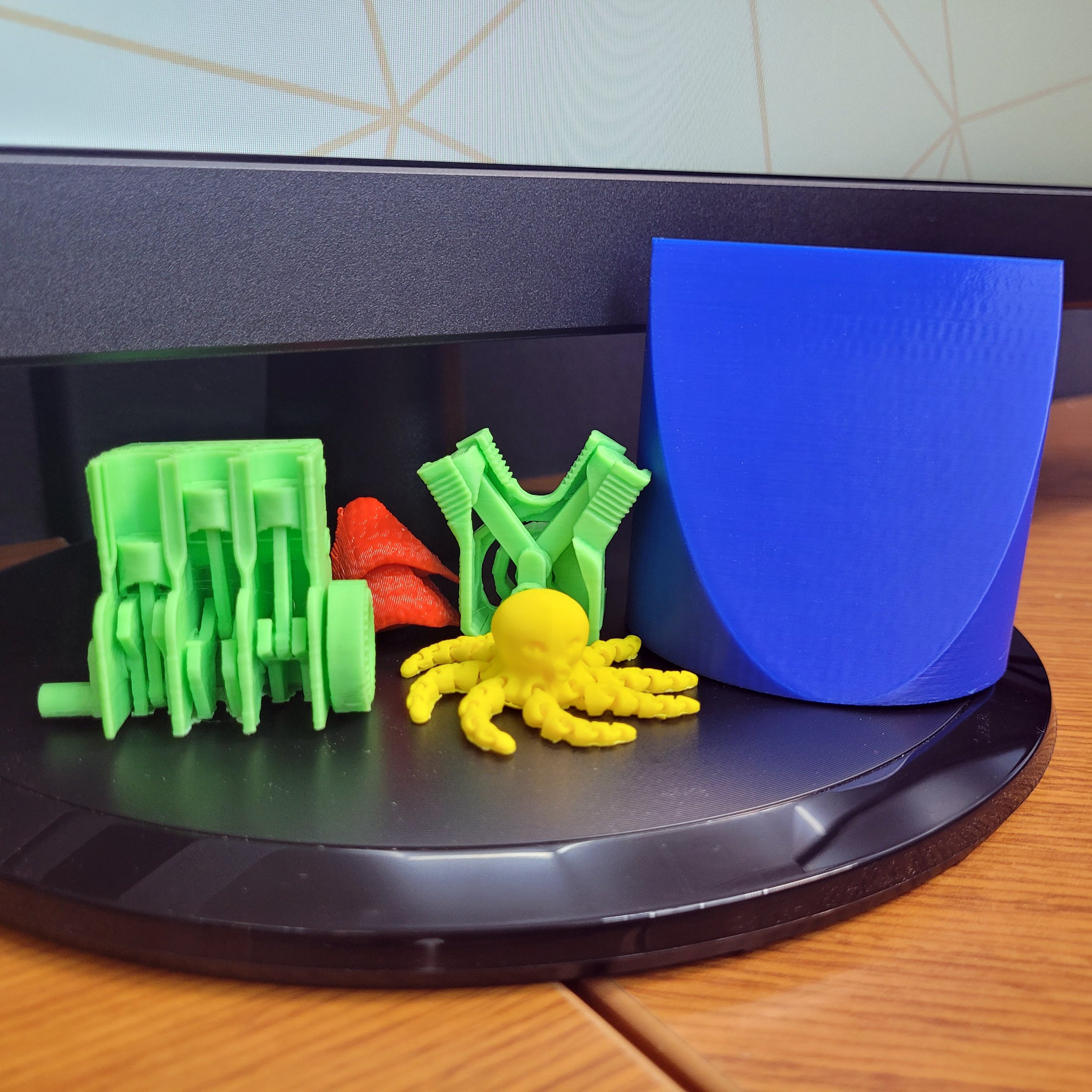

Myth 1: 3D Printing is Only for Plastic Trinkets and Toys

Truth: Additive manufacturing has come a long way from its humble beginnings. Today, it's used to create a vast array of products in industries such as aerospace, automotive, medical, and construction. Sure, you can still print those cute little plastic trinkets, but you can also print metal parts, prosthetic limbs, dental implants, and even entire houses! The materials used in AM have expanded to include metals, ceramics, and even composites, pushing the boundaries of what's possible.

Myth 2: 3D Printing is Always Faster and Cheaper

Truth: This one's a bit tricky. While AM can be faster and more cost-effective for certain applications, it's not always the case. For one-off prototypes, complex geometries, and small production runs, 3D printing shines. However, for large-scale manufacturing with simple designs, traditional methods may still reign supreme. Assessing the right manufacturing method requires a case-by-case analysis, considering factors such as material, production volume, and design complexity.

Myth 3: 3D Printed Parts are Weak and Fragile

Truth: Contrary to popular belief, 3D-printed parts can be incredibly strong and durable. While it's true that some early 3D-printed objects were prone to breakage, technology has evolved dramatically. Now, by using advanced materials and optimized print settings, AM can produce parts with mechanical properties rivaling those of traditionally manufactured parts. In some cases, 3D printed parts even surpass the strength of their counterparts, thanks to innovative design possibilities like lattice structures.

Myth 4: Additive Manufacturing is Bad for the Environment

Truth: It's easy to assume that 3D printing is a resource-intensive process, but in reality, it can be quite eco-friendly. AM has the potential to reduce material waste through precise, layer-by-layer deposition, as well as enable lightweight designs that save energy in transportation and usage. Moreover, 3D printing can promote local manufacturing, reducing the need for long-distance shipping. While it's essential to consider the energy consumption and material sourcing for AM, the technology has the potential to be a more sustainable alternative when used wisely.

Myth 5: 3D Printing Will Replace Traditional Manufacturing

Truth: Although additive manufacturing is a game-changer, conventional production techniques will still be used in some cases. Consider it as a supplementary technique instead. While traditional techniques continue to be efficient and cost-effective for large-scale production and simpler designs, additive manufacturing (AM) shines in areas like quick prototyping, complicated geometries, and personalization. Utilizing the distinctive benefits of both technologies will enable a more creative, productive, and environmentally friendly manufacturing sector in the future.

After we debunked the top five misconceptions about additive manufacturing, it should be clear that this is a flexible, developing technology with enormous promise. We can deploy AM effectively and keep pushing the limits of innovation if we have a clear knowledge of its genuine potential and constraints. So you'll know better the next time someone claims that 3D printing is only used for plastic toys. If you’re looking for a 3D-printed solution contact us today to get started or get a quote here.